从工业设施到个人车辆,机油泄漏是一个常见而又关键的问题,可能发生在各种环境中。如果置之不理,可能会对机器造成重大损坏、对环境造成危害并导致昂贵的维修费用。了解原因、识别迹象并采取有效的解决方案来管理机油泄漏对个人和企业都至关重要。

什么是漏油?

当油品因损坏、磨损或操作失误而从容器中漏出时,就会发生油品泄漏。这种情况可能发生在发动机、工业机器、管道和储油罐中。如果不及时处理,即使是轻微泄漏也会升级为严重问题。

漏油的常见原因

1. 退化的密封件和垫圈

随着时间的推移,密封件和垫圈会因热量、压力和老化而失去功效。这种退化往往会导致泄漏。

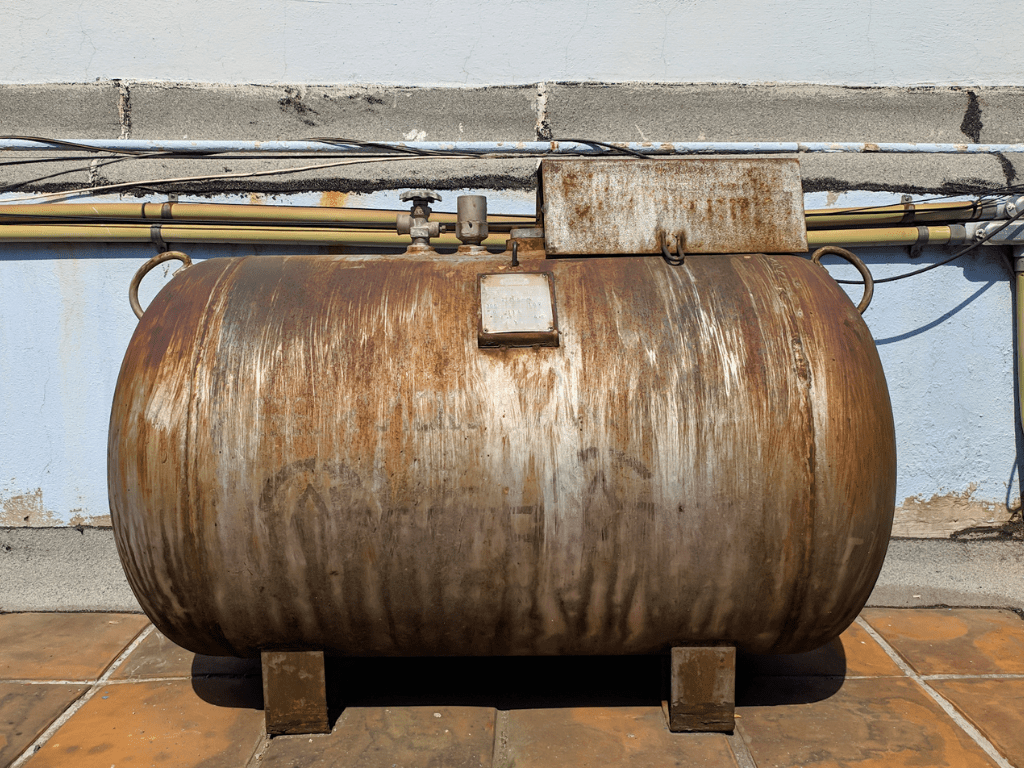

2. 油箱或油管腐蚀

储油罐和输油管很容易腐蚀,尤其是在维护不当的情况下。锈蚀和裂缝会造成油品泄漏。

3. 安装不当

滤油器、垫圈或油箱等部件安装不正确会导致密封不良,从而导致泄漏。

4. 机械损伤

外部撞击、振动或磨损会损坏机器和存储设备,导致漏油。

5. 压力过大

高压条件会迫使油从系统的薄弱点流出,尤其是在管道和工业机械中。

石油泄漏的风险和后果

1. 环境污染

油类泄漏会污染土壤、水道和海洋生态系统。这种破坏往往是长期的,会影响野生动物和植被。

2. 火灾和爆炸危险

石油极易燃烧。在工业环境或热源附近发生泄漏可能会导致火灾或爆炸。

3. 运行停机时间

工业泄漏会导致运营中断,造成延误和经济损失。

4. 维修成本高

处理漏油造成的后果往往比预防性维护更昂贵。

5. 健康风险

接触泄漏的油类会带来健康风险,包括呼吸道问题和皮肤过敏。

识别漏油

1. 可见油斑

地面、机器或设备上的油渍是泄漏的明显迹象。

2. 油位降低

经常加满机油而没有明显的消耗,说明可能存在泄漏。

3. 异常气味

如果机器或储藏区附近有强烈的油味,则可能是泄漏的信号。

4. 性能问题

机油不足的机器通常运行效率较低,并可能产生异常噪音。

如何管理和修复漏油

1. 检查并确定源头

彻底检查机器、管道或储罐,找出泄漏源。查看是否有密封件磨损、部件腐蚀或连接松动。

2. 维修或更换组件

更换损坏的密封件、垫圈或腐蚀部件。拧紧松动的接头,确保所有部件安装正确。

3. 使用溢油清洁剂

要有效处理溢出物,可使用环保清洁剂,如 AQUAQUICK 2000, 它能分解石油而不对环境造成危害。

4. 升级为耐用材料

在管道、水箱和密封件上改用高质量、耐腐蚀的材料,以降低未来发生泄漏的风险。

5. 监测和维护

执行定期检查和维护计划,及早发现潜在问题。

防止漏油

1. 定期维护

对机器和设备进行例行检查和及时维修可以防止发生泄漏。

2. 正确安装

确保所有部件的安装都符合制造商的规格要求,以避免密封问题。

3. 投资优质组件

使用高质量的密封件、垫圈和管道可以延长系统的使用寿命,降低泄漏的可能性。

4. 使用可生物降解的清洁液

如果发生意外泄漏,可使用生物降解产品,如 AQUAQUICK 2000 确保清理工作既有效又环保。

AQUAQUICK 2000 在处理漏油方面的作用

AQUAQUICK 2000 是一种创新型可生物降解溢油清洁剂,旨在以环保方式处理泄漏和溢出。其水基配方适用于汽车、船舶和制造业等多个行业。

AQUAQUICK 2000 的主要功能:

- 可生物降解,对环境安全

- 对所有类型的油类都有效

- 易于在工业和家庭环境中使用

应用:

- 清洁机器和地板上的溢油

- 净化受影响的土壤或水

- 管理海洋和工业环境中的泄漏问题

结论

油类泄漏不仅仅是一个麻烦;它还是一个严重的问题,可能会损害机器、中断运营并破坏环境。通过了解原因、识别迹象并采取预防措施,您可以最大限度地降低与油类泄漏相关的风险和成本。要进行有效的清理,请相信 AQUAQUICK 2000该技术是一种安全、环保的解决方案,既能确保彻底清洁,又能保护环境。定期维护和及时行动是有效预防和管理漏油的关键。