I. Introduction

Industrial tank cleaning plays a pivotal role in maintaining safety standards, ensuring operational efficiency, and complying with regulatory requirements within industrial settings. Tanks are integral components of various industries, including oil and gas, chemical manufacturing, wastewater treatment, and more. Regular cleaning and maintenance of these tanks are crucial for preventing accidents, minimizing environmental impact, and sustaining optimal performance levels.

This comprehensive guide aims to provide valuable insights and practical tips for industrial tank cleaning processes. Whether you’re a facility manager, maintenance personnel, or environmental health and safety professional, this guide will equip you with the knowledge and techniques necessary to effectively clean and maintain industrial tanks.

II. Understanding Industrial Tank Cleaning

Definition and Significance of Industrial Tank Cleaning

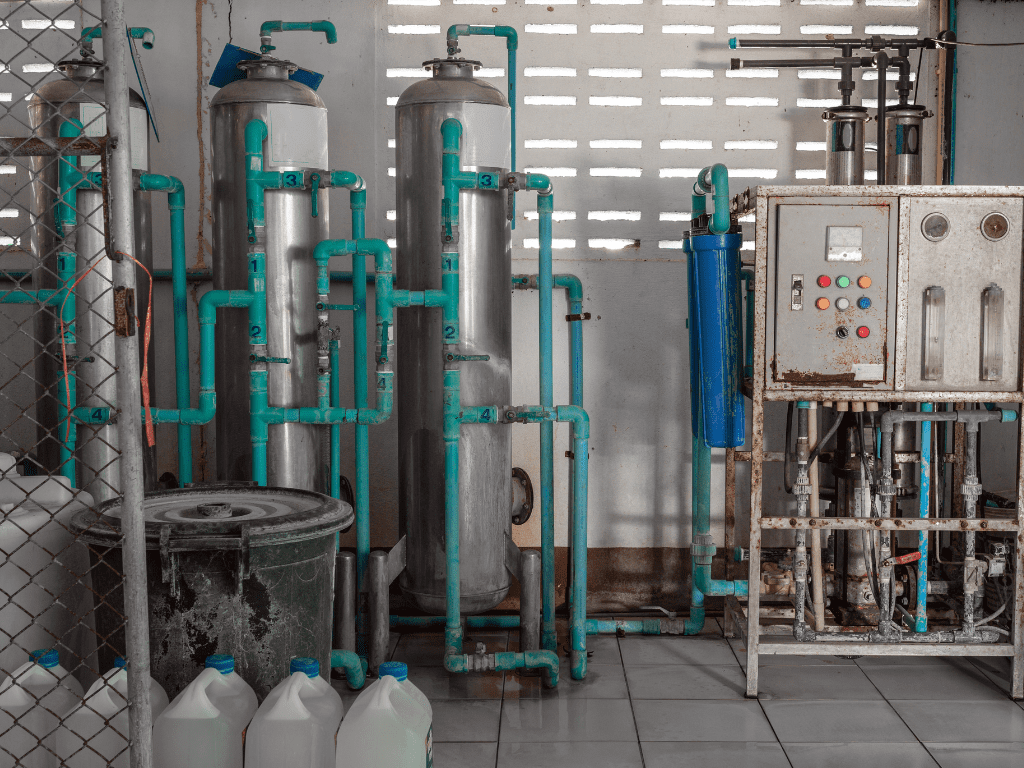

Industrial tank cleaning refers to the process of removing residues, contaminants, and other unwanted substances from storage tanks and vessels used in industrial operations. These tanks can vary in size, shape, and material composition, depending on their intended purpose and the industry they serve.

The significance of industrial tank cleaning cannot be overstated. Accumulated residues and contaminants pose serious risks to safety, environmental sustainability, and operational efficiency. Without proper cleaning and maintenance, tanks can become breeding grounds for hazardous substances, leading to potential accidents, product contamination, and regulatory violations.

Types of Tanks Commonly Cleaned in Industrial Settings

Industrial tanks encompass a wide range of types and applications. Some common types of tanks cleaned in industrial settings include:

- Oil Tanks: Used for storing various types of oil, including crude oil, petroleum products, and lubricants.

- Chemical Tanks: Designed to store chemicals used in manufacturing processes, such as acids, solvents, and corrosive substances.

- Storage Tanks: General-purpose tanks used for storing liquids, gases, or bulk materials in industrial facilities.

Each type of tank presents unique challenges and considerations for cleaning, depending on the substances stored, tank material, and operating conditions.

Importance of Regular Tank Maintenance and Cleaning

Regular tank maintenance and cleaning are essential for several reasons:

- Prevention of Contamination: Regular cleaning helps prevent the buildup of contaminants and residues that can compromise product quality and safety.

- Operational Efficiency: Clean tanks facilitate smoother operations, minimizing downtime and maximizing productivity.

- Regulatory Compliance: Many industries are subject to strict regulations governing tank maintenance and environmental protection. Regular cleaning helps ensure compliance with these regulations and avoids costly penalties.

By prioritizing regular maintenance and cleaning schedules, industrial facilities can prolong the lifespan of their tanks, mitigate risks, and maintain a safe and sustainable working environment.

III. Factors Influencing Tank Cleaning

Industrial tank cleaning is influenced by various factors, each of which plays a crucial role in determining the most suitable cleaning methods and strategies. Understanding these factors is essential for planning and executing effective tank cleaning operations.

Environmental Considerations

Environmental considerations are paramount in industrial tank cleaning operations. Spills, leaks, and improper disposal of cleaning agents can have significant environmental consequences, including soil and water contamination, harm to wildlife, and regulatory violations. Therefore, tank cleaning procedures must be designed and executed with environmental stewardship in mind, employing eco-friendly cleaning agents and proper waste management practices.

Types of Substances Stored in Tanks

The type of substances stored in tanks greatly influences the cleaning process. Different substances, such as oils, chemicals, and wastewater, require specific cleaning agents and techniques tailored to their properties and characteristics. For example, oil tanks may require degreasing agents to remove oily residues, while chemical tanks may necessitate neutralization steps to safely handle corrosive substances.

Tank Size and Configuration

The size and configuration of tanks also impact the cleaning process. Large tanks with complex geometries may require specialized equipment and techniques to ensure thorough cleaning and prevent the buildup of residues in hard-to-reach areas. Additionally, tank accessibility and the presence of internal structures, such as baffles and agitators, can further complicate cleaning operations and require careful planning and execution.

Regulatory Requirements and Compliance Standards

Regulatory requirements and compliance standards govern industrial tank cleaning practices to protect worker safety, environmental integrity, and public health. These regulations may include guidelines for waste disposal, emissions control, and spill prevention. Compliance with these standards is non-negotiable for industrial facilities, as failure to adhere to regulatory requirements can result in legal consequences, financial penalties, and reputational damage.

By considering these factors and incorporating them into their cleaning protocols, industrial facilities can ensure safe, efficient, and compliant tank cleaning operations.

IV. Oil Spill Management in Industrial Tank Cleaning

Oil spills present significant challenges to industrial operations and the environment during tank cleaning processes. Understanding the causes, impacts, and preventive measures is crucial for effective management and Industrial Tank Cleaning.

Explanation of Oil Spills and Their Impact

Oil spills occur when petroleum products leak or are inadvertently released during tank cleaning, posing threats to both industrial facilities and the environment. The impacts of oil spills are far-reaching:

- Operational Disruptions: Oil spills can lead to downtime, equipment damage, and financial losses for industrial facilities, disrupting production schedules and causing operational inefficiencies.

- Environmental Damage: Spilled oil contaminates soil, water bodies, and air, endangering ecosystems, aquatic life, and human health. Cleanup efforts can be prolonged and costly, with long-term effects on affected environments.

- Regulatory Compliance: Non-compliance with environmental regulations can result in fines, penalties, and reputational damage for businesses. Adherence to stringent regulatory standards is essential to prevent spills and minimize their impact.

Strategies for Oil Spill Prevention During Tank Cleaning

Preventive measures are essential to minimize the risk of oil spills during tank cleaning operations:

- Routine Maintenance: Regular inspection and maintenance of tanks help identify potential issues such as leaks, corrosion, or structural weaknesses before they escalate into spills.

- Proper Training: Providing comprehensive training to personnel involved in tank cleaning operations ensures they are equipped with the knowledge and skills to handle equipment safely and respond effectively to potential spill incidents.

- Secondary Containment: Implementing secondary containment measures, such as berms or barriers, helps confine spills and prevent them from spreading to the environment.

- Spill Response Plans: Developing and implementing spill response plans outlining procedures for containment, cleanup, and reporting in the event of an oil spill ensures swift and effective response to mitigate environmental impact.

V. Techniques for Industrial Tank Cleaning

Various techniques are employed to ensure effective industrial tank cleaning, depending on the nature of contaminants and tank configurations.

Mechanical Cleaning Methods

Mechanical cleaning methods involve physical removal of residues and contaminants from tank surfaces using equipment such as:

- Scraping: Manual or mechanized scraping is used to remove solid deposits and buildup from tank walls and floors.

- Brushing: Wire brushes or rotating brushes dislodge stubborn residues and coatings, facilitating their removal.

- High-Pressure Washing: Utilizing high-pressure water jets to remove loose debris, sludge, and coatings from tank surfaces, ensuring thorough cleaning.

Chemical Cleaning Agents and Solutions

Chemical cleaning agents play a vital role in dissolving and removing stubborn contaminants from tank surfaces. Common chemical solutions include:

- Solvent-Based Cleaners: Effective in dissolving oil, grease, and hydrocarbon-based residues, facilitating their removal from tank surfaces.

- Alkaline Cleaners: Used to break down organic materials and mineral deposits, particularly effective in food processing or wastewater treatment tanks.

- Acidic Cleaners: Employed to remove mineral scale, rust, and inorganic deposits from tank surfaces, restoring cleanliness and integrity.

VI. Best Practices for Safe and Effective Tank Cleaning

Adhering to best practices is essential for safe and effective tank cleaning operations, protecting personnel, the environment, and operational integrity.

Importance of Proper Training

Comprehensive training of personnel involved in tank cleaning operations ensures they understand equipment handling, spill response procedures, and safety protocols, minimizing risks and ensuring efficient performance.

Use of Personal Protective Equipment (PPE) and Safety Protocols

Utilizing appropriate personal protective equipment (PPE), including protective clothing, respiratory protection, eye and face protection, and fall protection, safeguards workers against potential hazards during tank cleaning operations. Adherence to strict safety protocols further minimizes risks and ensures regulatory compliance.

Implementation of Risk Assessment and Mitigation Strategies

Conducting comprehensive risk assessments before tank cleaning operations identifies potential hazards and allows for the implementation of mitigation strategies. This includes selecting appropriate cleaning methods, chemicals, and equipment, as well as adopting innovative solutions like AQUAQUICK 2000 for safer and more thorough cleaning processes. Regular monitoring and evaluation of cleaning operations help identify emerging risks and implement corrective actions as needed.

VII. Steps for Tank Cleaning Process

Industrial tank cleaning is a systematic process that involves several essential steps to ensure thoroughness, safety, and regulatory compliance. Following these steps diligently minimizes risks, enhances cleaning effectiveness, and maintains operational integrity.

1. Pre-Cleaning Preparations

Before initiating the cleaning process, thorough preparations are necessary to assess potential hazards and ensure a safe working environment:

- Inspection of Tank Condition: Evaluate the tank’s structural integrity, identifying any signs of corrosion, leaks, or damage that could pose risks during cleaning.

- Drainage, Ventilation, and Isolation: Ensure proper drainage of liquids and gases from the tank to minimize environmental impact and reduce explosion hazards. Adequate ventilation prevents the accumulation of hazardous vapors, while isolating the tank from other systems prevents cross-contamination.

2. Risk Assessment and Safety Measures

Conducting a comprehensive risk assessment is critical to identify potential hazards and implement appropriate safety measures:

- Thorough Risk Assessment: Evaluate potential risks associated with the cleaning process, including chemical exposure, confined spaces, and equipment operation. Implement safety protocols to mitigate identified risks.

- Emergency Response Procedures: Develop and communicate clear emergency response procedures to address unforeseen incidents promptly. Effective communication protocols ensure swift action and minimize disruptions.

3. Selection of Cleaning Methods and Agents

Choosing the right cleaning methods and agents is essential for effective removal of contaminants while minimizing environmental impact:

- Evaluation of Tank Type and Contaminants: Assess the type of tank and the nature of contaminants to determine the most suitable cleaning methods and agents. Consider factors such as tank material, size, and the specific types of residues present.

- Consultation with Experts: Seek advice from cleaning experts or suppliers to identify effective and safe cleaning solutions tailored to the unique requirements of the tank and its contents.

- Consideration of AQUAQUICK GLOBAL Products: Explore the use of AQUAQUICK GLOBAL products, known for their breakthrough-cleaning technology that ensures efficient and environmentally friendly cleaning solutions.

4. Execution of Cleaning Process

With preparations complete, proceed with the execution of the cleaning process:

- Application of Mechanical and Chemical Cleaning Methods: Employ mechanical methods such as scraping, brushing, or high-pressure washing to remove stubborn residues. Use chemical cleaning agents and solutions to dissolve and dislodge contaminants, facilitating their removal.

- Utilization of AQUAQUICK 2000: Incorporate AQUAQUICK 2000 into the cleaning process to enhance effectiveness. Its efficient emulsification and encapsulation of hydrocarbons enable thorough cleaning without the need for cutting or entry into the tank, reducing risks to personnel and the environment.

- Integration of Automated Systems: Utilize automated cleaning systems to streamline the process, enhancing efficiency and precision while minimizing human intervention.

5. Monitoring and Quality Control

Regular monitoring and quality control checks ensure that the cleaning process meets required standards:

- Regular Monitoring and Inspection: Conduct periodic inspections throughout the cleaning process to assess progress and identify any deviations from the plan.

- Testing for Cleanliness: Perform tests to verify cleanliness levels and ensure compliance with regulatory standards, confirming the effectiveness of the cleaning process.

6. Post-Cleaning Procedures

After completing the cleaning process, thorough post-cleaning procedures are necessary to wrap up operations and maintain regulatory compliance:

- Proper Disposal of Waste Materials: Dispose of waste materials in accordance with applicable regulations, ensuring environmentally responsible practices.

- Inspection and Restoration: Inspect the tank to ensure that it has been thoroughly cleaned and restored to operational status. Address any maintenance or repair needs promptly.

- Documentation for Regulatory Compliance: Maintain detailed documentation of the cleaning process, including records of inspections, tests, and disposal activities, to demonstrate compliance with regulatory requirements.

By following these systematic steps for tank cleaning, industrial facilities can ensure safe, efficient, and environmentally responsible operations while maintaining compliance with regulatory standards.

VIII. Future Trends in Industrial Tank Cleaning

As technology continues to advance and environmental sustainability becomes increasingly important, the future of industrial tank cleaning is poised for significant developments:

Emerging Technologies and Sustainable Solutions

- Robotics and Automation: The integration of robotics and automated systems will continue to revolutionize tank cleaning processes, enhancing efficiency and safety.

- Green Cleaning Agents: The adoption of environmentally friendly cleaning agents and solutions will rise, driven by the demand for sustainable practices and regulatory pressure.

- Remote Monitoring and Control: Remote monitoring technologies will enable real-time monitoring of tank conditions and cleaning progress, optimizing resource allocation and minimizing environmental impact.

Potential Regulatory Changes Impacting the Industry

- Stricter Environmental Regulations: Anticipated regulatory changes will likely impose stricter requirements on industrial facilities regarding tank cleaning practices, emphasizing the need for compliance and accountability.

- Emission Reduction Initiatives: Regulatory initiatives aimed at reducing emissions and minimizing environmental pollution will drive the adoption of cleaner and more efficient tank cleaning technologies and methods.

IX. Conclusion

In conclusion, industrial tank cleaning is indispensable for maintaining safety, compliance, and efficiency in industrial operations. It is vital for preventing contamination, ensuring regulatory adherence, and safeguarding both personnel and the environment. Prioritizing tank maintenance and cleaning is paramount to uphold operational integrity and environmental responsibility. By staying informed about emerging trends and technologies, industries can drive continuous improvement in tank cleaning practices. Notably, solutions like AQUAQUICK 2000 offer breakthrough advancements, ensuring effective and affordable cleaning while promoting sustainability. As we move forward, a concerted effort towards responsible tank cleaning practices will be crucial for sustaining both operational excellence and environmental stewardship.