Industrial oil spills present significant environmental and economic challenges, requiring effective solutions to mitigate their impact. Industrial oil spill solutions encompass a range of strategies and technologies designed to prevent, control, and remediate as an industrial oil spill solution. This article delves into various industrial oil spill solutions, exploring preventive measures, response strategies, and innovative technologies to address this critical issue.

Understanding Industrial Oil Spills

Industrial oil spills occur when oil or petroleum products are accidentally released into the environment, often due to equipment failure, human error, or natural disasters. These spills can have devastating effects on ecosystems, wildlife, and human health. Therefore, implementing robust industrial oil spill solutions is essential to minimize the damage and ensure a swift recovery.

Preventive Measures

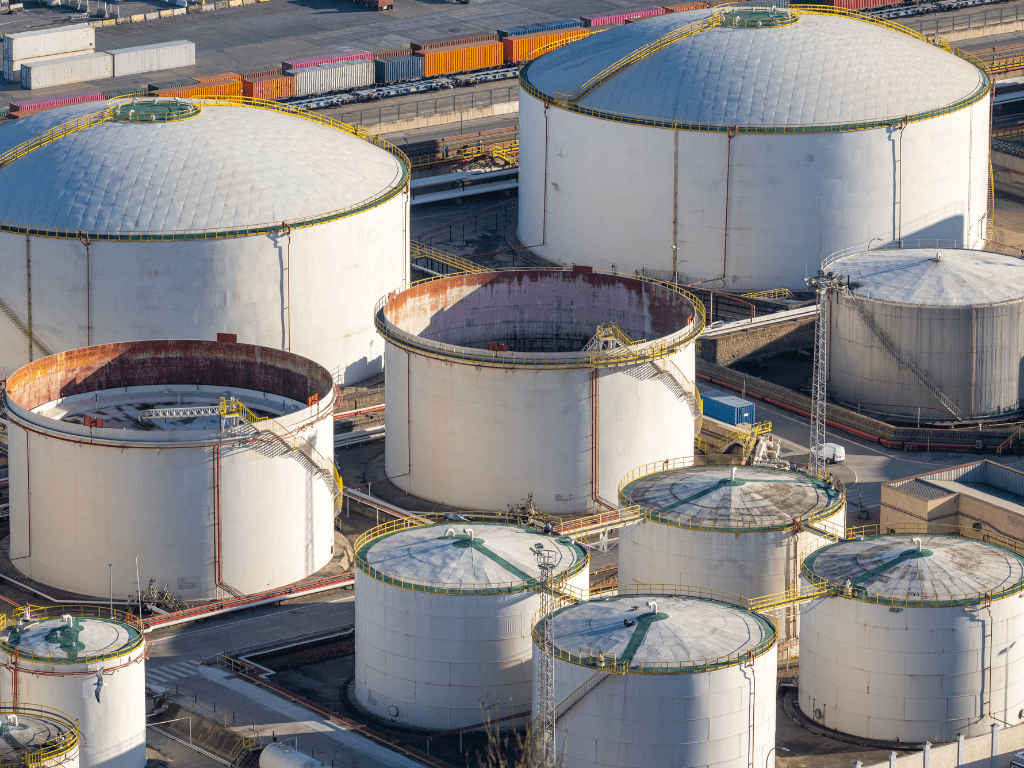

1. Regular Maintenance and Inspection

One of the most effective industrial oil spill solutions is regular maintenance and inspection of equipment. This involves routine checks of pipelines, storage tanks, and machinery to identify and address potential weaknesses before they lead to spills. By adhering to strict maintenance schedules and employing advanced monitoring technologies, industries can significantly reduce the risk of oil spills.

2. Employee Training and Safety Protocols

Proper training for employees is crucial in preventing oil spills. Workers should be well-versed in safety protocols, emergency response procedures, and the correct handling of hazardous materials. Regular drills and workshops can enhance their preparedness and reduce the likelihood of human error, making this an integral part of industrial oil spill solutions.

3. Advanced Containment Systems

Investing in advanced containment systems is another key aspect of industrial oil spill solutions. Secondary containment systems, such as bunds and berms, can effectively prevent spilled oil from spreading. These barriers are designed to contain the oil within a specific area, allowing for easier cleanup and minimizing environmental impact.

Response Strategies

4. Emergency Response Teams

Establishing dedicated emergency response teams is a vital component of industrial oil spill solutions. These teams should be equipped with the necessary tools and training to respond quickly and effectively to oil spills. Rapid response can significantly reduce the extent of environmental damage and facilitate a faster recovery process.

5. Oil Spill Containment Booms

Oil spill containment booms are floating barriers used to contain and control the spread of oil on water surfaces. These booms are essential industrial oil spill solutions for spills that occur in marine or freshwater environments. By preventing the oil from spreading, containment booms make it easier to recover the spilled oil and protect sensitive ecosystems.

6. Skimmers and Absorbents

Skimmers and absorbents are critical tools in industrial oil spill solutions. Skimmers are devices that remove oil from the water surface, while absorbents are materials that soak up the oil. These tools are used in tandem to efficiently recover spilled oil and minimize environmental contamination. Modern skimmers are highly effective and can be deployed rapidly in spill scenarios.

Innovative Technologies

7. Bioremediation

Bioremediation is a cutting-edge industrial oil spill solution that involves the use of microorganisms to break down and degrade oil contaminants. This natural process accelerates the decomposition of oil, reducing its toxicity and environmental impact. Bioremediation is particularly effective in soil and water environments, making it a versatile tool in industrial oil spill solutions.

8. Chemical Dispersants

Chemical dispersants are substances that break down oil into smaller droplets, allowing it to disperse more easily in water. While controversial, these dispersants can be effective industrial oil spill solutions when used judiciously. They enhance the natural degradation of oil by increasing its surface area, facilitating microbial action and reducing the impact on shorelines and marine life.

9. Oil-Eating Enzymes

Oil-eating enzymes are another innovative approach to industrial oil spill solutions. These enzymes accelerate the breakdown of oil molecules, making it easier for natural processes to degrade the oil. Enzyme-based solutions are environmentally friendly and can be used in conjunction with other remediation techniques to enhance their effectiveness.

Case Studies

10. The Deepwater Horizon Spill

The Deepwater Horizon spill in 2010 is one of the most infamous industrial oil spills in history. The incident highlighted the need for robust industrial oil spill solutions. A combination of containment booms, skimmers, and chemical dispersants was used to manage the spill. Additionally, bioremediation techniques were employed to accelerate the cleanup process. The lessons learned from this disaster have led to significant advancements in industrial oil spill solutions.

11. The Exxon Valdez Spill

The Exxon Valdez spill in 1989 was another major event that underscored the importance of effective industrial oil spill solutions. In this case, mechanical recovery methods, such as skimmers and absorbents, played a crucial role in the cleanup efforts. The spill also spurred the development of improved response technologies and stricter regulatory measures to prevent future incidents.

Environmental Impact and Recovery

12. Ecosystem Restoration

Restoring ecosystems affected by oil spills is a critical aspect of industrial oil spill solutions. This involves rehabilitating contaminated habitats, replanting vegetation, and monitoring wildlife populations. Ecosystem restoration aims to return the environment to its pre-spill condition, ensuring the long-term health and sustainability of the affected areas.

13. Long-Term Monitoring

Long-term monitoring is essential to assess the effectiveness of industrial oil spill solutions and ensure that the environment fully recovers. This involves regular sampling and analysis of soil, water, and air quality to detect any residual contamination. Monitoring helps identify potential issues and guides ongoing remediation efforts.

14. Community Involvement

Engaging local communities in oil spill response and recovery efforts is a key component of successful industrial oil spill solutions. Community involvement ensures that the concerns and needs of affected populations are addressed. Public awareness campaigns and educational programs can also promote environmental stewardship and prevent future spills.

Regulatory Framework

15. Government Regulations

Government regulations play a crucial role in enforcing industrial oil spill solutions. Regulatory bodies establish standards for oil spill prevention, response, and remediation. Compliance with these regulations is mandatory for industries, ensuring that best practices are followed to minimize the risk and impact of oil spills.

16. International Cooperation

International cooperation is essential in addressing industrial oil spills that have cross-border implications. Organizations such as the International Maritime Organization (IMO) and regional agreements facilitate collaboration between countries to implement effective industrial oil spill solutions. Sharing knowledge, resources, and technologies enhances global preparedness and response capabilities.

Future Directions

17. Advanced Sensing Technologies

The development of advanced sensing technologies is revolutionizing industrial oil spill solutions. Drones, satellites, and remote sensors can detect and monitor oil spills in real-time, providing valuable data for rapid response. These technologies enable more accurate assessments of spill size, location, and movement, enhancing the effectiveness of cleanup efforts.

18. Artificial Intelligence and Machine Learning

Artificial intelligence (AI) and machine learning are being increasingly integrated into industrial oil spill solutions. AI algorithms can analyze vast amounts of data to predict spill behavior, optimize response strategies, and improve decision-making processes. Machine learning models can also enhance the efficiency of oil spill detection and monitoring systems.

19. Green Technologies

The adoption of green technologies is a promising trend in industrial oil spill solutions. Eco-friendly materials, such as biodegradable absorbents and non-toxic dispersants, are being developed to minimize environmental impact. Additionally, renewable energy sources and sustainable practices are being incorporated into oil spill prevention and response strategies.

20. Public-Private Partnerships

Public-private partnerships are essential in advancing industrial oil spill solutions. Collaboration between governments, industries, and research institutions fosters innovation and ensures the availability of resources for effective spill management. These partnerships facilitate the development and implementation of cutting-edge technologies and best practices.

AQUAQUICK 2000: The Ultimate Industrial Oil Spill Solution

Industrial oil spills are a serious environmental concern, posing significant threats to ecosystems, wildlife, and human health. The need for effective, eco-friendly solutions is more pressing than ever. Among the various options available, AQUAQUICK 2000 stands out as one of the best industrial oil spill solutions. This article explores what makes AQUAQUICK 2000 a superior choice and why it is highly recommended for addressing industrial oil spills.

Understanding AQUAQUICK 2000

AQUAQUICK 2000 is an environmentally friendly, water-based cleaning agent specifically designed for the rapid and efficient removal of oil and other hydrocarbons from contaminated surfaces and environments. Developed with a focus on sustainability and effectiveness, AQUAQUICK 2000 has gained a reputation as a go-to solution for industrial oil spills.

Key Features of AQUAQUICK 2000

- Biodegradability: AQUAQUICK 2000 is 100% biodegradable, ensuring that its use does not introduce harmful chemicals into the environment. Unlike many traditional oil spill solutions that can leave toxic residues, AQUAQUICK 2000 breaks down naturally, reducing long-term environmental impact.

- Non-Toxic Composition: This cleaning agent is non-toxic to humans, animals, and marine life, making it a safe choice for use in diverse ecosystems. The non-toxic nature of AQUAQUICK 2000 ensures that remediation efforts do not inadvertently harm the very environments they aim to protect.

- Versatility: AQUAQUICK 2000 is effective on a wide range of surfaces and environments, including soil, water, and hard surfaces. Its versatility makes it suitable for various industrial applications, from marine oil spills to land-based contamination.

- Rapid Action: The formula of AQUAQUICK 2000 allows for quick emulsification and dispersion of oil, facilitating faster cleanup processes. This rapid action is crucial in minimizing the spread of contaminants and reducing overall environmental damage.

- Ease of Application: AQUAQUICK 2000 can be applied using standard equipment such as sprayers, pressure washers, and manual application tools. This ease of use ensures that response teams can deploy the solution quickly and efficiently, even in challenging conditions.

Why AQUAQUICK 2000 is the Best Industrial Oil Spill Solution

1. Environmental Safety

AQUAQUICK 2000’s environmental credentials are unmatched. Its biodegradable and non-toxic composition ensures that it poses no threat to wildlife, aquatic life, or human health. This is particularly important in industrial settings where spills can affect both the immediate environment and surrounding areas. Using AQUAQUICK 2000 minimizes the risk of secondary pollution, making it a truly green solution.

2. Efficiency in Oil Removal

The primary goal of any industrial oil spill solution is to remove the contaminant quickly and effectively. AQUAQUICK 2000 excels in this regard, with its rapid action formula that breaks down oil into smaller, more manageable droplets. This emulsification process makes it easier to collect and remove the oil, significantly speeding up the cleanup operation.

3. Cost-Effectiveness

While the initial cost of some oil spill solutions can be prohibitive, AQUAQUICK 2000 offers a cost-effective alternative without compromising on performance. Its efficiency means that less product is required to achieve effective results, and the reduced environmental impact can lead to lower long-term remediation costs. Additionally, its ease of application reduces labor costs and downtime.

4. Regulatory Compliance

Environmental regulations are becoming increasingly stringent worldwide. Industries are required to use products that meet high environmental standards to avoid hefty fines and legal issues. AQUAQUICK 2000 complies with international environmental regulations, providing industries with a reliable solution that helps them adhere to legal requirements while effectively managing oil spills.

5. Versatile Applications

The versatility of AQUAQUICK 2000 makes it suitable for a wide range of applications. Whether dealing with a marine oil spill, a pipeline rupture, or a factory floor contamination, AQUAQUICK 2000 can be effectively used in various scenarios. This adaptability makes it an ideal choice for industries looking for a single solution to multiple spill scenarios.

6. Proven Effectiveness

Numerous case studies and real-world applications have demonstrated the effectiveness of AQUAQUICK 2000. Its proven track record in diverse environments and spill conditions provides confidence to industries that they are choosing a reliable and tested solution. The success stories associated with AQUAQUICK 2000 highlight its capability to handle even the most challenging oil spill situations.

Case Studies Highlighting AQUAQUICK 2000

Marine Oil Spill Response

In a significant marine oil spill incident, AQUAQUICK 2000 was deployed to manage the contamination. The product’s rapid emulsification properties facilitated the quick dispersion of the oil, preventing it from spreading further and affecting marine life. The cleanup operation was completed in record time, with minimal environmental impact, showcasing the effectiveness of AQUAQUICK 2000 in marine environments.

Industrial Facility Spill

An industrial facility experienced a major oil leak, threatening nearby water bodies and soil. AQUAQUICK 2000 was used to treat the contaminated areas. Its ease of application allowed the response team to quickly cover a large area, breaking down the oil and enabling efficient removal. The site was restored to its pre-spill condition with minimal disruption to the facility’s operations.

AQUAQUICK 2000 stands out as one of the best industrial oil spill solutions available today. Its environmentally friendly composition, rapid action, versatility, and proven effectiveness make it a top choice for industries looking to manage oil spills responsibly and efficiently. By choosing AQUAQUICK 2000, industries can ensure that their spill response efforts are both effective and sustainable, protecting the environment and adhering to regulatory standards. Whether dealing with a small spill or a large-scale disaster, AQUAQUICK 2000 provides a reliable, cost-effective solution that minimizes environmental impact and supports swift recovery.

Conclusion

Industrial oil spill solutions are critical in mitigating the environmental and economic impacts of oil spills. By implementing preventive measures, employing advanced response strategies, and leveraging innovative technologies, industries can effectively address oil spills and ensure the protection of ecosystems and communities. Ongoing research, regulatory frameworks, and international cooperation are essential to further enhance industrial oil spill solutions and safeguard our environment for future generations.