Engine corrosion is a common and costly issue that affects vehicles and machinery, impacting performance and longevity. Corrosion can lead to frequent repairs, unexpected breakdowns, and even permanent damage to engine parts. In this article, we’ll delve into the causes of engine corrosion, preventive strategies, and effective cleaning solutions, including AQUAQUICK 2000, to keep your engine components in optimal condition. This guide provides practical steps on how to prevent engine corrosion risks and ensure your engine’s peak performance.

What Causes Engine Corrosion?

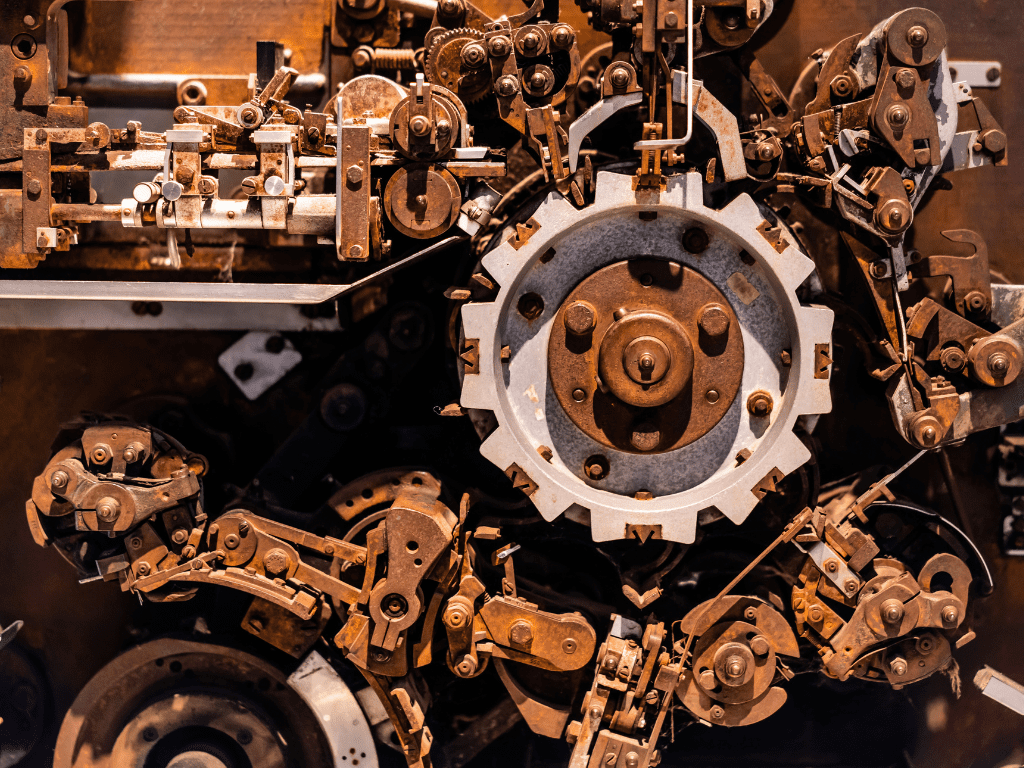

Corrosion in engines is primarily a result of chemical reactions between metal surfaces and environmental factors like moisture, contaminants, and oxygen. Over time, these interactions deteriorate engine components, leading to compromised performance.

Moisture and Humidity

One of the primary causes of engine corrosion is exposure to moisture and high humidity. When metal components within the engine come in contact with water vapor, oxidation occurs, forming rust. This is especially common in regions with high humidity levels or in vehicles that are frequently exposed to rain or condensation.

Salt and Other Contaminants

Salt, often from road salt in colder climates or marine environments, is another major contributor to engine corrosion. Salt accelerates the corrosion process by acting as an electrolyte, which speeds up the chemical reaction between metal and oxygen, leading to quicker rust formation. Dust, dirt, and other contaminants can also trap moisture, creating an ideal environment for corrosion.

Exhaust Gases and Pollutants

Internal combustion engines produce exhaust gases that contain sulfur compounds and other pollutants, which can corrode metal surfaces over time. When combined with moisture, these gases form acidic compounds that can eat away at engine components.

Understanding Different Types of Corrosion in Engines

Engine corrosion can vary based on the type of metal and exposure conditions, each affecting the engine differently. The most common types include oxidation, galvanic corrosion, and pitting:

- Oxidation occurs when metal reacts with oxygen in the presence of moisture, creating rust. This is the most common type of engine corrosion and is usually seen on iron or steel components.

- Galvanic Corrosion happens when two different metals come into contact in a corrosive environment, causing one metal to corrode faster than the other.

- Pitting Corrosion creates small, localized holes that weaken the structure of the engine part and are harder to detect until severe damage occurs.

Knowing the types of engine corrosion helps understand how to prevent engine corrosion effectively by focusing on each area’s unique needs, including regular cleaning and maintenance.

Effects of Engine Corrosion

Engine corrosion affects performance, efficiency, and lifespan. As metal parts degrade, engines can experience:

- Reduced fuel efficiency due to frictional losses and leaks.

- Higher repair costs as corroded parts need frequent replacement.

- Increased breakdowns and potential safety issues if left unchecked.

Preventing corrosion is essential to avoid these impacts and to maintain reliable engine operation.

The Impact of Poor Maintenance on Engine Corrosion

Lack of regular maintenance is a major contributor to engine corrosion. Dirt, oil, and other contaminants can trap moisture against metal surfaces, creating an ideal environment for rust. When engines are not cleaned or maintained, these contaminants speed up the corrosion process, eventually damaging the engine and its components.

By understanding how to prevent engine corrosion through maintenance practices like oil changes, coolant checks, and part inspections, you can protect your engine’s longevity. Using effective cleaning agents like AQUAQUICK 2000 as part of your maintenance routine helps in preventing the build-up of contaminants, thus slowing down the corrosion process.

How to Prevent Engine Corrosion

Understanding the causes of corrosion allows for implementing targeted prevention strategies. Here are some of the most effective methods:

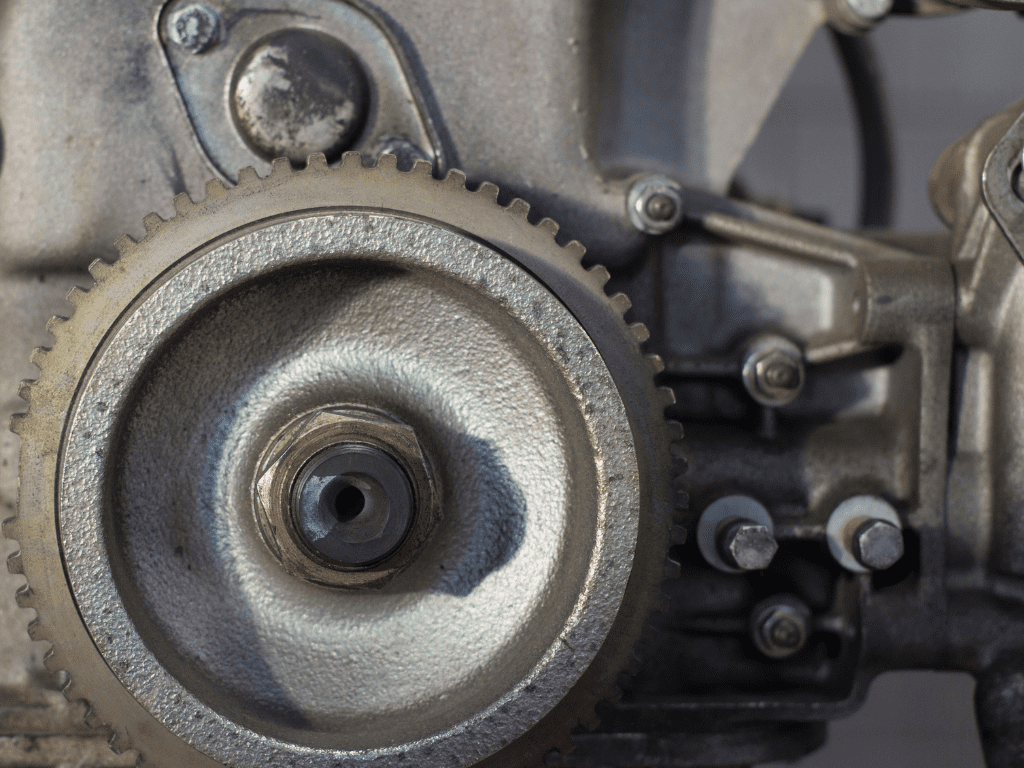

Regular Cleaning and Maintenance

Cleaning engine parts regularly can help remove contaminants that lead to corrosion. Using specialized cleaning agents like AQUAQUICK 2000, designed for industrial engines and parts, ensures a thorough clean without harming sensitive materials. AQUAQUICK 2000 is an effective solution for engines that encounter tough contaminants like oil, grease, and dirt. Its formula is environmentally friendly, free from hazardous acids and solvents, and ensures your engines remain clean and corrosion-free.

Rust-Proofing and Coatings

Applying rust-proof coatings to engine parts creates a protective layer that shields metal surfaces from moisture and pollutants. These coatings can significantly extend the life of engine components, especially in areas prone to high humidity or salt exposure.

Use of Coolants and Additives

Engine coolants and additives play a role in preventing corrosion inside the engine. Modern coolants contain corrosion inhibitors that protect the engine’s internal parts, particularly aluminum and other metals susceptible to rust. Ensure that you use high-quality coolants that are compatible with your engine and follow manufacturer recommendations for coolant changes.

Regular Oil Changes

Regular oil changes help to maintain engine cleanliness and remove acidic byproducts that contribute to corrosion. Over time, engine oil can become contaminated with moisture and pollutants, creating an acidic environment that accelerates rusting. By changing oil regularly, you minimize the risk of internal corrosion.

Proper Storage Conditions

If you store vehicles or equipment for extended periods, ensure they are kept in dry, temperature-controlled environments. Consider using moisture-absorbing agents or covers to reduce exposure to humidity and condensation. This is especially important for seasonal vehicles or machinery that are stored during colder months.

The Role of AQUAQUICK 2000 in Corrosion Prevention

AQUAQUICK 2000 is a powerful cleaning agent developed specifically for engines and other industrial components that experience heavy buildup of grease, oil, and contaminants. Regular cleaning with AQUAQUICK 2000 helps in several ways:

- Dirt and Grease Removal: The formulation of AQUAQUICK 2000 effectively lifts grease, oil, and dirt, ensuring these contaminants don’t contribute to corrosion by trapping moisture.

- Non-Corrosive Formula: Unlike many industrial cleaners that contain strong acids or alkalis, AQUAQUICK 2000 is designed to be safe for metals, coatings, rubber, and other sensitive materials.

- Environmental Safety: AQUAQUICK 2000 avoids the use of toxic and environmentally harmful chemicals, making it a responsible choice for businesses focused on sustainability.

For businesses or individuals facing difficult-to-clean surfaces on engines and parts, AQUAQUICK 2000 offers a reliable solution. Its gentle yet effective formula is ideal for preventing corrosion by thoroughly cleaning and protecting your engine components.

How to Use AQUAQUICK 2000 for Best Results

Step 1: Prepare the Area

Ensure the engine is cool and the area is well-ventilated. Place absorbent materials beneath the engine to capture any runoff during cleaning.

Step 2: Apply AQUAQUICK 2000

Spray AQUAQUICK 2000 directly onto the surfaces with heavy grease, dirt, or contaminants. Allow it to sit for a few minutes to penetrate and lift the grime.

Step 3: Agitate and Rinse

Use a brush to gently scrub any stubborn areas. Rinse thoroughly with water to remove any residue, revealing a clean, corrosion-free surface. Repeat as necessary for heavily stained parts.

Step 4: Dry and Inspect

Ensure all parts are dry before reassembling or using the engine. This final drying step helps to prevent any residual moisture from causing corrosion.

Additional Tips to Avoid Engine Corrosion

Along with using AQUAQUICK 2000 and the preventive strategies above, consider these additional tips to keep your engine in top shape:

Avoid Driving Through Deep Water

Water can infiltrate engine components, leading to rust formation, particularly if the water contains salt or other contaminants. Avoid driving through flooded areas, and if exposure to water is unavoidable, clean and dry the engine as soon as possible.

Regularly Inspect for Signs of Corrosion

Frequent inspections of your engine can help catch early signs of corrosion, allowing you to address them before they worsen. Look for signs of rust on visible metal parts and check for any leaks or other damage.

Use High-Quality Fuel

Contaminated or low-quality fuel can introduce impurities into the engine that may contribute to corrosion. Stick to reputable fuel sources, and consider using fuel additives that help reduce moisture accumulation in the fuel system.

Consider Stainless Steel or Coated Parts

For components that are highly prone to corrosion, consider replacing them with stainless steel or specially coated alternatives. These materials are more resistant to corrosion and can be a worthwhile investment, especially in harsh environments.

Common Myths About Engine Corrosion and Prevention

There are a few myths surrounding how to prevent engine corrosion that can lead to ineffective practices:

- Myth 1: “Only older engines rust.” The truth is, any engine exposed to moisture and contaminants is susceptible to corrosion, regardless of its age.

- Myth 2: “Painting the engine blocks corrosion completely.” While painting can provide a barrier, it doesn’t prevent corrosion on unpainted surfaces or inside the engine.

- Myth 3: “Corrosion only occurs on external engine parts.” In reality, internal engine corrosion can be just as damaging, making coolant and oil maintenance essential.

By addressing these misconceptions, you can focus on proven, effective ways to prevent corrosion, including the regular use of non-corrosive cleaning solutions like AQUAQUICK 2000.

Conclusion

Engine corrosion is a preventable issue that, if left unchecked, can lead to costly repairs and reduced performance. By understanding what causes engine corrosion and implementing effective preventive measures, you can keep your engine in optimal condition for years to come. Regular cleaning with high-quality products like AQUAQUICK 2000 can play a crucial role in corrosion prevention, especially for engines that encounter oil, grease, and harsh contaminants regularly.

Whether it’s regular maintenance, rust-proofing, or using top-quality coolants and cleaning agents, each step contributes to extending your engine’s life and maintaining its efficiency. Embrace these practices, and you’ll reduce the likelihood of corrosion, ensuring reliable engine performance and longevity.