I. Introduction to Grease Trap Cleaning

Grease traps play a vital role in maintaining the functionality of plumbing systems, particularly in commercial kitchens and food establishments. These traps are designed to intercept fats, oils, grease, and food particles from wastewater, preventing them from entering sewer lines where they could cause blockages and environmental hazards. Regular cleaning of grease traps is essential to ensure their effectiveness and prevent costly plumbing issues.

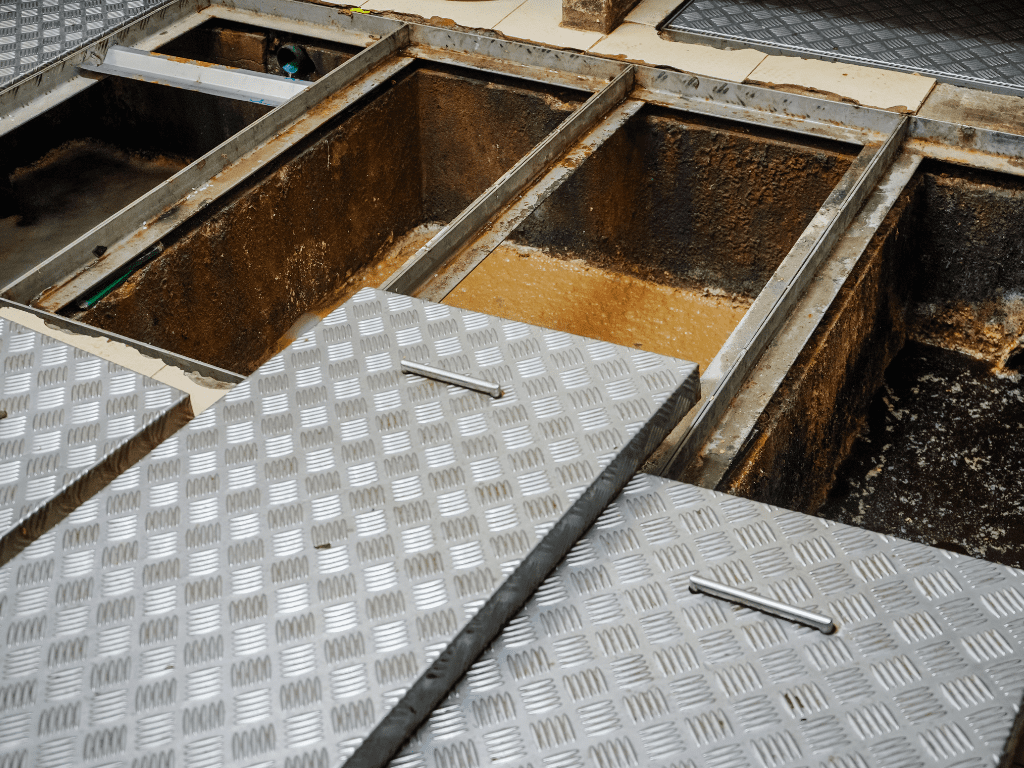

II. Understanding Grease Traps

Grease traps, also known as grease interceptors or grease recovery devices, are plumbing devices installed in kitchens and food service establishments to trap and intercept grease and solids before they enter the wastewater disposal system. These traps come in various types, including passive grease traps that rely on gravity to separate grease from water and automatic grease traps equipped with mechanical components for more efficient separation.

Proper sizing and placement of grease traps are critical for their effective operation. Factors such as the volume of wastewater generated, the size of the establishment, and local regulations determine the appropriate size and location of grease traps. Incorrect sizing or placement can lead to inadequate grease removal and potential plumbing issues.

III. Factors Contributing to Grease Trap Buildup

Grease trap buildup occurs due to the accumulation of fats, oils, grease, and food particles that are washed down sinks and drains in commercial kitchens and food service establishments. Over time, these substances can solidify and form blockages within the grease trap, reducing its capacity and efficiency.

Common substances contributing to grease trap buildup include:

1. Fats, Oils, and Grease (FOG):

Cooking oils, fats, and grease from food preparation activities are major contributors to grease trap buildup. When washed down drains, these substances solidify and adhere to the walls of the grease trap, forming layers of residue that impede water flow.

2. Food Particles:

Solid food particles, such as meat scraps, vegetable peels, and dairy products, can also accumulate in grease traps, further exacerbating blockages and reducing the trap’s capacity to capture grease.

3. Soap and Detergents:

While necessary for cleaning dishes and utensils, soaps and detergents used in commercial kitchens can contribute to grease trap buildup. These substances can emulsify grease, making it more difficult for the trap to capture and retain grease effectively.

4. Lack of Maintenance:

Neglecting regular cleaning and maintenance of grease traps can lead to accelerated buildup and blockages. Without proper maintenance, grease traps become less efficient over time, increasing the risk of plumbing backups and environmental pollution.

Understanding the factors contributing to grease trap buildup is crucial for implementing effective cleaning and maintenance strategies to ensure the proper functioning of these essential plumbing devices.

IV. Steps for Cleaning a Grease Trap

Cleaning a grease trap is a crucial maintenance task to ensure its proper function and prevent plumbing issues. Here’s a detailed guide on how to clean a grease trap effectively, including safety precautions, equipment needed, techniques for draining and cleaning, integration of AquaQuick, and inspection for damage or leaks.

1. Preparing for the Cleaning Process

Before starting the cleaning process, it’s essential to take necessary precautions and gather the required equipment:

Safety Precautions:

- Wear appropriate protective gear, including gloves, goggles, and apron, to protect against exposure to grease and cleaning agents.

- Ensure adequate ventilation in the area to prevent inhalation of fumes from cleaning agents.

- Turn off power to any nearby electrical equipment to avoid accidents.

Gathering Necessary Equipment:

- Bucket or container for collecting grease and waste.

- Scraping tools or spatulas to remove solidified grease and debris.

- Grease trap pump or vacuum truck for draining the trap.

- Cleaning brushes or scrubbers to clean the trap interior.

- AquaQuick cleaning agent (if using).

2. Draining the Grease Trap

Properly draining the grease trap is essential to remove trapped grease and waste effectively:

Techniques for Safely Removing Trapped Grease and Waste:

- Use scraping tools or spatulas to loosen and remove solidified grease and debris from the trap walls and baffles.

- Carefully scoop out the collected grease and waste into a designated container for disposal.

- Avoid pouring hot water down the drain before cleaning, as it can melt grease and make it more challenging to remove.

Proper Disposal Methods for Collected Materials:

- Dispose of collected grease and waste according to local regulations and guidelines.

- Avoid pouring grease down the drain or disposing of it in the trash, as it can lead to environmental pollution and plumbing issues.

- Consider recycling options for grease, if available in your area.

3. Scrubbing and Cleaning the Trap

Once the grease trap is drained, it’s time to clean the trap interior to remove remaining grease and residue:

Using Appropriate Cleaning Agents and Tools:

- Choose a suitable cleaning agent for grease trap cleaning, such as AquaQuick.

- Apply the cleaning agent to the trap interior, focusing on areas with stubborn grease buildup.

- Use cleaning brushes or scrubbers to scrub the trap walls and baffles thoroughly.

4. Integration of AquaQuick in the Cleaning Solution:

- AquaQuick is a highly effective grease trap cleaning agent specifically designed for grease trap cleaning.

- Its unique formula breaks down grease and organic matter, making it easier to remove during cleaning.

- AquaQuick is environmentally friendly and biodegradable, making it a safe option for grease trap maintenance.

Introduction to AquaQuick as a Cleaning Agent:

- AquaQuick is a liquid concentrate formulated to dissolve grease, fats, oils, and organic matter commonly found in grease traps.

- Its powerful surfactants penetrate and emulsify grease, allowing for easy removal during cleaning.

- AquaQuick is safe to use on a variety of surfaces, including metal, plastic, and concrete.

Benefits of Using AquaQuick for Grease Trap Cleaning:

- Highly effective at breaking down and removing grease buildup, reducing the need for manual scrubbing.

- Environmentally friendly and biodegradable, minimizing environmental impact.

- Cost-effective solution compared to traditional cleaning agents.

- Easy to apply and rinse off, saving time and labor during the cleaning process.

Application Methods and Dosage Guidelines:

- Follow the manufacturer’s instructions for diluting and applying AquaQuick.

- Typically, AquaQuick is diluted with water before application, with dosage recommendations based on the size and condition of the grease trap.

- Apply the diluted solution evenly to the trap interior, ensuring thorough coverage of all surfaces.

5. Inspecting for Damage or Leaks

After cleaning the grease trap, it’s essential to inspect the trap for any damage or leaks:

Importance of Routine Maintenance Checks:

- Regular maintenance checks help identify potential issues early and prevent costly repairs.

- Inspect the trap for cracks, leaks, or signs of corrosion that may compromise its integrity.

Addressing Any Issues Promptly to Prevent Further Damage:

- If damage or leaks are detected, take immediate steps to address the issue.

- Depending on the severity of the damage, repairs may be necessary to ensure the trap’s continued function.

By following these steps and integrating AquaQuick into the cleaning solution, you can effectively clean and maintain your grease trap, ensuring optimal performance and longevity. Regular maintenance and proper cleaning techniques are essential for preventing plumbing issues and ensuring compliance with environmental regulations.

V. Professional vs. DIY Grease Trap Cleaning

When it comes to cleaning grease traps, establishments have the option to either hire professionals or undertake the task themselves. Each approach comes with its own set of advantages and disadvantages, which are important to consider before making a decision.

Advantages and Disadvantages of Hiring Professionals:

Expertise and Equipment:

- Advantages: Professional grease trap cleaning companies have the expertise and specialized equipment necessary to thoroughly clean and maintain grease traps. They are trained in effective cleaning techniques and have access to high-powered equipment such as grease trap pumps and vacuum trucks.

- Disadvantages: Hiring professionals can be more expensive than DIY grease trap cleaning methods, as you are paying for their expertise and equipment.

Cost Considerations:

- Advantages: While hiring professionals may come with a higher upfront cost, it can save money in the long run by preventing costly plumbing issues and ensuring the longevity of the grease trap.

- Disadvantages: Depending on the frequency of cleaning and the size of the grease trap, the cost of professional services can add up over time.

Risks and Challenges of DIY Grease Trap Cleaning:

Potential Safety Hazards:

- Advantages: DIY Grease trap cleaning allows establishments to have more control over the cleaning process and eliminates the need to rely on external service providers.

- Disadvantages: DIY cleaning can pose safety hazards, especially when handling potentially hazardous materials such as grease and cleaning agents. Without proper training and equipment, individuals may be at risk of exposure to harmful fumes or injury from handling heavy equipment.

Effectiveness Compared to Professional Services:

- Advantages: DIY grease trap cleaning can be effective if done correctly, especially for smaller grease traps with less buildup. It allows establishments to address minor issues promptly without having to wait for scheduled service appointments.

- Disadvantages: DIY cleaning may not be as thorough or effective as professional services, particularly for larger grease traps or those with heavy buildup. Improper cleaning techniques can lead to incomplete removal of grease and debris, resulting in recurring blockages and plumbing issues.

VI. Best Practices for Grease Trap Maintenance

Proper maintenance is essential for ensuring the effectiveness and longevity of grease traps. Implementing the following best practices can help establishments maintain clean and functional grease traps:

Implementing a Regular Cleaning Schedule:

- Establish a regular cleaning schedule based on the size of the grease trap and the volume of wastewater generated. Frequency recommendations may vary depending on usage and local regulations.

Proper Disposal of Grease and Waste:

- Dispose of collected grease and waste according to local regulations and guidelines to prevent environmental pollution. Consider recycling options for grease if available in your area.

Environmentally Friendly Practices:

- Use environmentally friendly grease trap cleaning agents and practices to minimize the impact on the environment. Choose biodegradable cleaning agents and avoid pouring harmful chemicals down the drain.

Compliance with Regulations and Guidelines:

- Ensure compliance with local regulations and guidelines for grease trap cleaning and maintenance. Failure to comply with regulations can result in fines and penalties.

Monitoring and Troubleshooting:

- Regularly monitor the grease trap for signs indicating the need for cleaning or maintenance, such as slow drainage or foul odors. Address any issues promptly to prevent further damage or plumbing backups.

Proactive Measures to Prevent Issues:

- Take proactive measures to prevent grease trap issues, such as implementing grease management practices in the kitchen and educating staff on proper disposal techniques.

VII. Conclusion

In conclusion, maintaining clean and functional grease traps is essential for the proper operation of plumbing systems in commercial kitchens and food service establishments. Whether you choose to hire professionals or undertake DIY cleaning, it’s important to prioritize regular maintenance and compliance with regulations.

Furthermore, integrating AquaQuick into your grease trap cleaning regimen can significantly enhance the effectiveness of the cleaning process. AquaQuick’s powerful formula is specifically designed to break down grease, fats, oils, and organic matter, making it easier to remove during cleaning. Its environmentally friendly and biodegradable properties make it a safe and sustainable choice for grease trap maintenance.

By following best practices, implementing proactive measures, and utilizing products like AquaQuick, establishments can ensure optimal performance and longevity of their grease traps, ultimately preventing costly plumbing issues and environmental pollution.